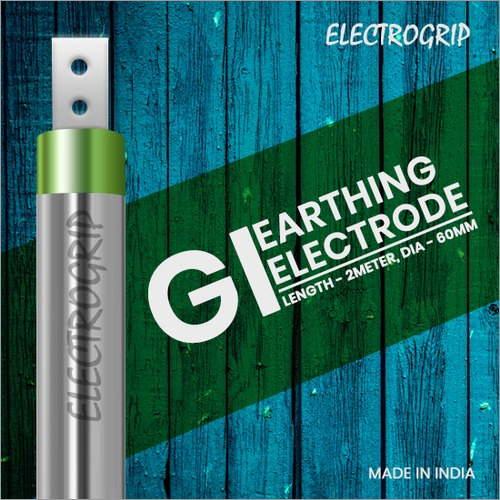

Electrogrip 60mm 2 Meter GI Earthing Electrode

Price 3450 INR/ Piece

Electrogrip 60mm 2 Meter GI Earthing Electrode Specification

- Copper Thickness

- Not Applicable (this model is GI, not copper bonded)

- Diameter

- 60mm

- Tensile Strength

- Almost 600 MPa (depending on GI composition)

- Life Span

- Up to 25 Years under standard conditions

- Strength

- High mechanical and corrosion resistance

- Purity

- Standard IS-grade GI material

- Product Type

- GI Earthing Electrode

- Material

- Galvanized Iron (GI)

- Application

- Electrical grounding for buildings, substations, towers, and industrial plants

- Function

- Earthing/grounding for electrical safety

- Shape

- Cylindrical Rod

- Surface Treating

- Galvanized Iron (GI) finish

- Tolerance

- 3% on dimensions

- Dimension (L*W*H)

- 60mm diameter x 2 meters length (Height)

- Weight

- Approx. 11-15 kg (varies with manufacturer)

- Color

- Silver/Grey (GI coating)

- Packing Type

- Poly wrap or wooden crate packing

- Corrosion Protection

- 100% GI coating ensures high corrosion protection

- Operating Temperature Range

- -10C to +55C

- Maintenance

- Maintenance-Free Design

- Soil Compatibility

- Suitable for all types of soil

- Connection Terminal

- Bolt-in clamp compatible

- Outer Coating Thickness

- 80100 microns GI

- Rod Length

- 2000mm (2 meters)

- Inner Core

- Mild Steel per IS 2062 standards, fully galvanized

- Coating Standard

- IS 2629/IS 4759/BSEN ISO 1461 (as per manufacturer)

- Resistivity

- Low resistivity (improves current dissipation)

Electrogrip 60mm 2 Meter GI Earthing Electrode Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 24 Hours

About Electrogrip 60mm 2 Meter GI Earthing Electrode

Specification

| Coating Thickness | up to 100 microns |

| Usage/Application | Maintenance Free Chemical Earthing |

| Diameter | 60 mm |

| Packaging Type | Plastic Wrap |

| Color | Silver |

| Auger Hole | 8 - 10 inches |

| Terminal Hole | 8mm |

| Terminal Size | 60mm x 6mm |

| Certification | CPRI Certified |

| Service Life | 7 to 10 years |

| Brand | Electrogrip |

| Country of Origin | Made in India |

Durable GI Construction & Standards

Fabricated from high-purity galvanized iron, the Electrogrip electrode meets IS 2062 material standards and is fully galvanized as per IS 2629/IS 4759/BSEN ISO 1461. Its substantial outer GI coating provides enhanced longevity and performance even in aggressive soil environments, helping prevent corrosion over years of operation.

Effective Earthing for Electrical Safety

This 60mm diameter, 2-meter rod ensures efficient and safe grounding for a range of applications, including residential buildings, substations, industrial plants, and telecom towers. The low-resistivity core enables rapid dissipation of fault currents to earth, mitigating electrical hazards and safeguarding equipment and personnel.

Installation and Versatility

Designed for ease of installation, this electrode uses a bolt-in clamp terminal compatible with standard wiring systems. Its adaptability to all soil types makes it suitable for use across India, both for new installations and system upgrades. Poly wrap or wooden crate packing ensures it arrives safely on-site, ready for deployment.

FAQ's of Electrogrip 60mm 2 Meter GI Earthing Electrode:

Q: How is the Electrogrip 60mm GI Earthing Electrode installed?

A: This earthing electrode is typically installed by driving or burying the cylindrical rod vertically into the ground. The bolt-in clamp terminal allows secure connection to the earth conductor. Professional installation is recommended to ensure optimal soil contact and electrical safety.Q: What materials and standards are used in the manufacturing process?

A: The electrode is crafted from mild steel per IS 2062, fully galvanized to meet IS 2629/IS 4759/BSEN ISO 1461 standards. The outer GI coating ranges from 80-100 microns, providing robust corrosion protection and meeting IS-grade specifications for mechanical and chemical resistance.Q: When should this type of GI earthing electrode be used?

A: The 60mm GI earthing electrode is ideal for grounding requirements in buildings, industrial plants, substations, and telecom towers. Its high resistance to corrosion and mechanical stress makes it suitable for both new installations and the replacement of existing grounding systems.Q: Where can the Electrogrip GI Earthing Electrode be applied?

A: This electrode is designed for use in a wide variety of locations across India. Due to its robust design and effective soil compatibility, it can be installed in residential, commercial, and industrial sites-including areas with high soil resistivity or moisture content.Q: What are the key benefits of using this electrode over traditional earthing methods?

A: Advantages include maintenance-free operation, superior corrosion protection via a 100% GI coating, high mechanical strength (up to 600 MPa tensile strength), long service life (up to 25 years), and efficient current dissipation even in diverse soil conditions.Q: Is this electrode compatible with copper conductors and clamps?

A: While the electrode itself is galvanized iron (not copper bonded), its bolt-in clamp connection can accommodate standard copper earth wires or strips, provided that proper bimetallic connectors are used to prevent electrolysis.Q: How does the electrode ensure reliable grounding without ongoing maintenance?

A: The thick GI coating and robust construction provide reliable, consistent earthing with minimal degradation over decades, eliminating the need for routine maintenance typically required by traditional earth pits or chemical electrodes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GI Earthing Electrode Category

Electrogrip 50mm 3 Meter GI Earthing Electrode

Price 3450 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial, Commercial & Residential Earthing

Product Type : GI Earthing Electrode

Function : Electrical Grounding

Material : other, Galvanized Iron (GI)

Electrogrip 80mm 2 Meter GI Earthing Electrode

Price 3450 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial, residential, and commercial earthing systems

Product Type : GI Earthing Electrode

Function : Safe electrical earthing and dissipation of fault/current

Material : other, Galvanized Iron (GI)

Galvanised Iron Earthing Electrode

Price 3450 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Maintenance Free Chemical Earthing

Product Type : Earthing Rod

Function : Maintenance Free Chemical Earthing

Electrogrip 40mm 2 Meter GI Earthing Electrode

Price 3450 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Power Plant, Substations, Industrial, Residential Earthing

Product Type : GI Earthing Electrode

Function : Safe Dissipation of Fault Currents

Material : other, Galvanized Iron (GI)

|

ELAPP POWER PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry