Copper Bonded Earthing Electrode

Price 4500 INR/ Set

MOQ : 1 Set

Copper Bonded Earthing Electrode Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets, , Per Month

- Delivery Time

- 24 Hours

About Copper Bonded Earthing Electrode

Copper Bonded Earthing Electrode is an essential equipment which is designed for the grounding application and is high in demand due to its excellent resistance to the oxidation. The coper coated layer prevents the damages due to corrosion. This electrode is filled with a crystalline mixture which improves the conductivity of the whole system. The ends of the offered Copper Bonded Earthing Electrode are completely sealed to prevent leakages. It can be easily installed without the need of special attachments and requires less time for the installation.FAQs of Copper Bonded Earthing Electrode:

Q: What components are included in the Copper Bonded Earthing Electrode set?

A: The set comprises the GI Earthing Electrode, Back Fill Compound, and an Earth Pit Cover.Q: What are the available dimensions for the GI earthing electrode?

A: The GI earthing electrode is available in lengths of 2 meters and 3 meters, with diameters of 40mm, 50mm, 60mm, 80mm, and 90mm.Q: What is the resistivity value of the Back Fill Compound?

A: The Back Fill Compound offers a resistivity of 0.24 ohm-m.Q: How does the Back Fill Compound enhance the durability of the earthing system?

A: The anti-corrosive property of the Back Fill Compound protects the GI earthing electrode from corrosion, ensuring long-term effectiveness.Q: What is the load-bearing capacity of the Electrogrip Earth Pit Cover?

A: The Electrogrip Earth Pit Cover has a load-bearing capacity of up to 8 tons and is made of durable polypropylene.Q: What properties ensure the longevity of the GI earthing electrode?

A: The GI earthing electrode is coated with up to 100 microns of zinc, which provides durability and makes it last for 7 to 10 years.Q: What makes the Back Fill Compound effective for leakage current flow?

A: The Back Fill Compound is composed of several conductive components, allowing the leakage current to flow without hindrance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Copper Rod Category

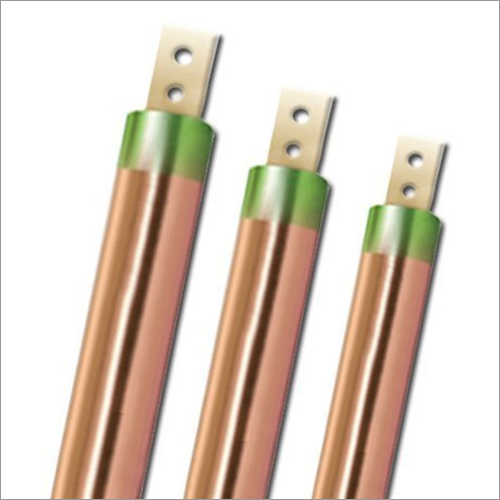

Earthing Copper Rod

Price 1000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Alloy : Other, NonAlloy

Shape : Round

Surface Treatment : Polished

Product Type : Other, Solid Earthing Copper Rod

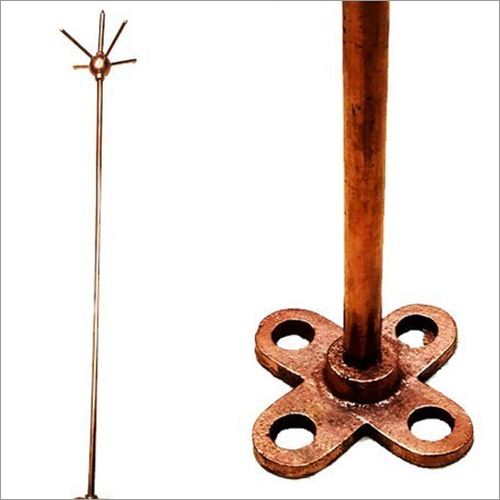

Copper Air Termination Rod

Price 4500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Alloy : No

Shape : Round, Round

Surface Treatment : Other, Smooth

Product Type : Copper Bars, Copper Bars

Threaded Copper Rod

Price 1000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Alloy : Yes

Shape : Round

Surface Treatment : Coated

Product Type : Copper Profile

|

ELAPP POWER PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry